Ingredients To Our Craftsmanship

Box Assembly Materials

Wood

Wood is a natural and versatile material widely used in cabinetry. Its natural beauty, with unique grain patterns and textures, adds warmth and character to any space. Wood can be shaped, carved, and customized to create intricate designs, making it suitable for various cabinet styles. Additionally, high-quality wood species used in cabinetry, such as oak, maple, or cherry, offer durability and longevity, ensuring cabinets can withstand daily use. With its timeless appeal and ability to be customized, wood remains a popular choice for cabinetry in both residential and commercial settings.

Features:

Natural beauty

Versatile and customizable

Durable and long-lasting

Applications:

Kitchen and bathroom cabinets

Custom storage solutions

Notes:

Choose wood species based on desired aesthetics and functionality

Apply finishes and treatments for enhanced appearance and durability

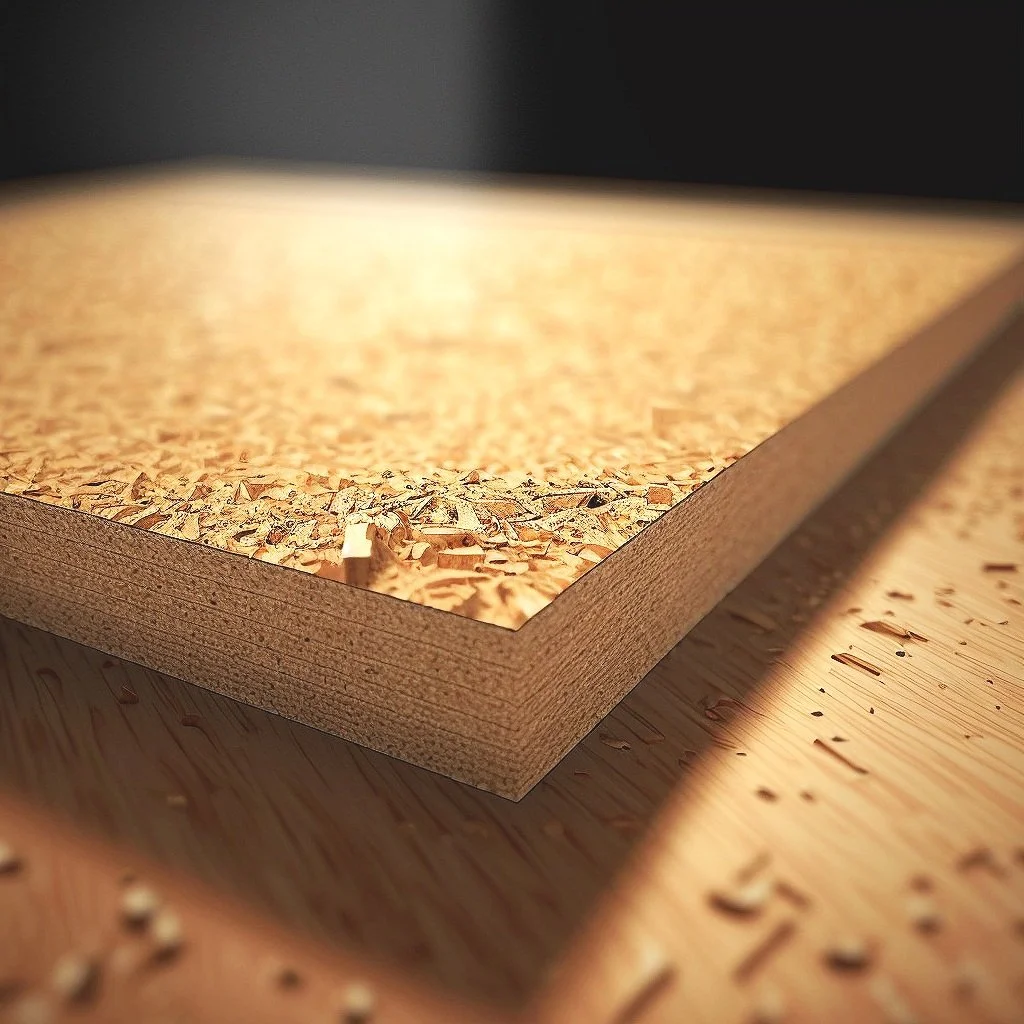

Particle Board

Unlock the potential of affordable cabinetry solutions with particle board. Engineered for cost-effectiveness, particle board provides a smooth and consistent surface that allows for a seamless finish in your cabinetry projects. Its lightweight nature and easy workability make it a convenient choice for cutting, shaping, and assembly. Particle board shines in budget-friendly projects and non-visible areas, offering functional properties without compromising on quality. While it may require protection against excessive moisture, particle board provides a reliable option for achieving your cabinetry goals without breaking the bank. Explore the versatility of particle board and create functional and stylish cabinets that meet your needs.

Features:

Affordability: Particle board is a cost-effective option for cabinetry, making it a budget-friendly choice for projects.

Smooth and Consistent Surface: Particle board provides a smooth and uniform surface, which can be beneficial for achieving a seamless look in cabinetry.

Easy to Work With: Particle board is relatively lightweight and easy to cut, shape, and assemble, making it convenient for cabinetry construction.

Applications:

Budget-Friendly Projects: Particle board is commonly used in projects with budget constraints, making it suitable for cost-effective cabinetry solutions.

Non-Visible Areas: Particle board is often utilized for cabinet interiors and non-visible components, where its affordability and functional properties can be advantageous.

Notes:

Limited Moisture Resistance: Particle board is prone to swelling and damage when exposed to excessive moisture, so it's essential to protect it from water sources in cabinetry applications.

Lamination or Veneer Options: Particle board can be laminated or veneered to enhance its appearance and provide better protection against moisture.

Considered less durable: Compared to solid wood or plywood, and particle board is generally less durable

High-Density Fiberboard

Elevate your cabinetry projects with the superior strength and durability of HDF (High-Density Fiberboard). Designed to withstand heavy use and resist warping, HDF provides a solid and stable foundation for your cabinets. Its high density ensures a smooth and uniform surface, allowing for precise cuts and seamless finishes. HDF is an excellent choice for applications where strength and durability are crucial, making it ideal for kitchen and bathroom cabinets that need to withstand daily wear and moisture exposure. Experience the reliability of HDF in your cabinetry, ensuring longevity and a polished look that stands the test of time.

Features:

Superior strength and durability

High density for a solid and stable structure

Resistant to warping, bending, and sagging

Smooth and uniform surface for precise cuts and finishes

Excellent dimensional stability

Applications:

Kitchen and Bathroom Cabinets: HDF's strength and resistance to moisture make it an ideal choice for cabinets in high-traffic areas prone to moisture exposure.

Furniture Construction: HDF can be used in the construction of sturdy furniture pieces, such as bookshelves, desks, and entertainment centers.

Interior Design Elements: HDF can be utilized for wall paneling, decorative moldings, and other interior design elements that require durability and a polished appearance.

Notes:

Moisture Resistance: While HDF is more resistant to moisture compared to other fiberboard options, it is still important to protect it from prolonged exposure to water or high humidity.

Surface Treatments: HDF can be easily painted, laminated, or veneered to enhance its appearance and provide additional protection.

Weight: HDF is relatively heavier compared to other fiberboards, which should be considered for installation and transportation purposes.

Plywood

Elevate your cabinetry projects with the superior strength and versatility of plywood. Designed to provide a durable and reliable material for your cabinets, plywood offers numerous benefits for your cabinetry needs. With its layered construction, plywood delivers excellent strength and stability, making it resistant to warping, bending, and sagging. Its smooth and consistent surface allows for precise cuts and finishes, ensuring a seamless and polished appearance. Plywood is an excellent choice for applications where strength, durability, and aesthetic appeal are essential.

Features:

Superior strength and durability

Layered construction for stability and resistance to warping

Smooth and consistent surface for precise cuts and finishes

Excellent dimensional stability

Applications:

Kitchen and Bathroom Cabinets: Plywood is an ideal choice for cabinetry in high-moisture areas, providing resistance to moisture and ensuring the longevity of your cabinets.

Furniture Construction: Plywood can be used to construct various furniture pieces, including bookshelves, desks, and entertainment centers, due to its strength and stability.

Interior Design Elements: Plywood can be utilized for wall paneling, decorative moldings, and other interior design elements, offering both durability and a natural aesthetic.

Notes:

Moisture Resistance: While plywood offers some resistance to moisture, it is important to protect it from prolonged exposure to water or high humidity.

Surface Treatments: Plywood can be easily painted, stained, or veneered to enhance its appearance and provide additional protection.

Weight: Plywood is relatively lightweight, making it easier to handle during installation and transportation.

Finishes

Melamine

Melamine is a versatile surface option for particleboard or MDF panels that can serve as an alternative to high pressure laminates in various settings. Its benefits include ease of cleaning, durability, water-resistance, scratch-resistance, and shatter-resistance. Compared to solid wood products, using melamine can also save time and money as it eliminates the need for sanding or finishing. With a diverse range of textures and natural wood grains available, melamine panels offer a cost-effective and adaptable solution for enhancing designs and projects.

However, it is important to note that although the material itself is waterproof, any water that seeps into the particleboard beneath could cause warping of the melamine. Moreover, improper installation could lead to damage to the particleboard substrate, resulting in chipping of the melamine. Since the edges of melamine boards are unfinished, it is necessary to use edge banding to conceal this area.

Features:

Highly durable – waterproof, resistant to scratching, stains, and shattering

Dimensionally stable and strong

Cost-effective option compared to high pressure laminates

Highly versatile

Available in a wide selection of textures and natural wood grains

Applications

Cabinets

Whiteboard

Shelving

Drawer Components

Furniture

Store Fixtures

Laboratory, hospitality, and medical furniture

Notes

Requires edgebanding

Also known as Thermally Fused Laminate (TFL) or Low Pressure Laminate (LPL)

High Pressure Laminate

Melamine is a versatile surface option for particleboard or MDF panels that can serve as an alternative to high pressure laminates in various settings. Its benefits include ease of cleaning, durability, water-resistance, scratch-resistance, and shatter-resistance. Compared to solid wood products, using melamine can also save time and money as it eliminates the need for sanding or finishing. With a diverse range of textures and natural wood grains available, melamine panels offer a cost-effective and adaptable solution for enhancing designs and projects.

However, it is important to note that although the material itself is waterproof, any water that seeps into the particleboard beneath could cause warping of the melamine. Moreover, improper installation could lead to damage to the particleboard substrate, resulting in chipping of the melamine. Since the edges of melamine boards are unfinished, it is necessary to use edge banding to conceal this area.

Features:

Highly durable – waterproof, resistant to scratching, stains, and shattering

Dimensionally stable and strong

Cost-effective option compared to high pressure laminates

Highly versatile

Available in a wide selection of textures and natural wood grains

Applications

Cabinets

Whiteboard

Shelving

Drawer Components

Furniture

Store Fixtures

Laboratory, hospitality, and medical furniture

Notes

Requires edgebanding

Also known as Thermally Fused Laminate (TFL) or Low Pressure Laminate (LPL)